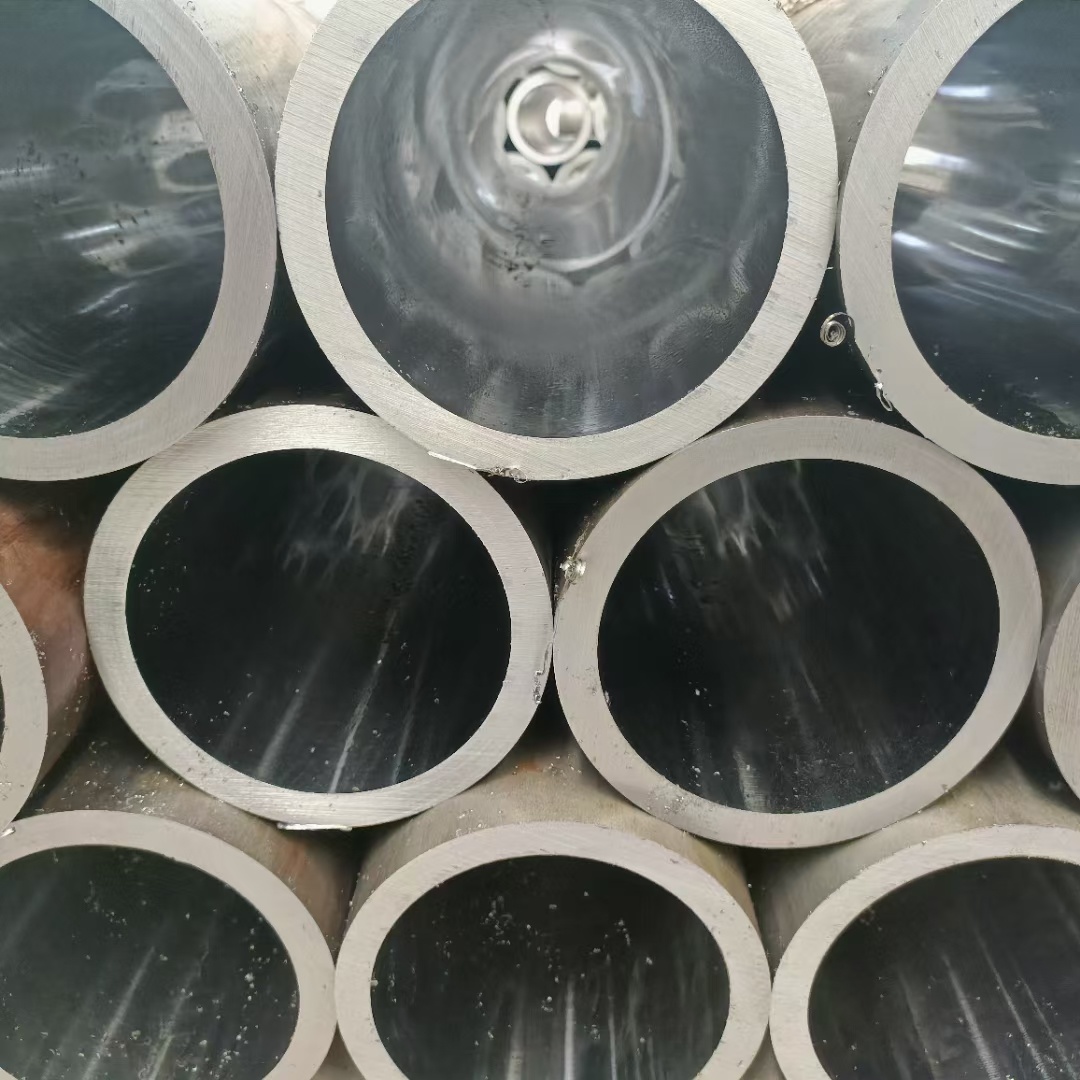

steel pipes carbon round pipes S45C SCM435 650$/Ton

outline:

Tubes for thermal equipment. Superheating pipes, high temperature and high-pressure boiler pipes for locomotive boilers.

key word:

seamless steel pipe,carbon steel pipe

Category:

Product Details

| Product name | 80mm diameters round seamless carbon steel pipe |

| Standard | ASTM,JIS3445,DIN2391,EN10305-1,GB/T3639 |

| Material | ASTM A106B, ASTM A53B, API 5L Gr.B,ST52, ST37,ST44 SAE1010/1020/1045,S45C/CK45,SCM435,AISI4130/4140 |

| Outer diameter | 10mm-426mm |

| Wall thickness | 1-100mm |

| Length | 3-12M or as required |

| Tolerance | Control with in the standard, OD:+/-1%, WT:+/-5% |

| Surface treatment | Black/Peeling/Polishing/Machined |

| Technique | Hot rolled/cold rolled |

| Heat Treatment | Annealed; Quenched; Tempered |

| price terms | FOB,CFR,CIF,EXW all acceptable |

| Delivery Detail | Inventory About 3-5 days; custom-made 10-15 days;riding to order's quantity |

| Loading port | Tainjian port, China |

| Packing | Standard export packing |

| Payment Terms | T/T, L/C at sight, etc |

| Product | Seamless Pipe,Seamless Carbon Steel Pipe,Carbon Steel Seamless Pipe |

| Application | For converying gas, water & oil for Fluids Transmission |

| Size | OD: 10.3-1219.2mm |

| WT: 1.65-60mm | |

| LENGTH: 5.8/6/11.8/12m | |

| Pipe Standard | API 5L |

| ASTM A106 | |

| JIS G3454,G3455,G3456 | |

| DIN1629/EN10216-1 | |

| EN 10208 |

1.For pipelines. Water, gas pipes, steam pipes, and oil and gas trunk lines. 2. Tubes for thermal equipment. Superheating pipes, high temperature and high-pressure boiler pipes for locomotive boilers. 3. For the machinery industry. Aviation structural tubes, automobile axle tubes, tractor structural tubes, etc.

Packing Method

1.. Wooden boxes package,PVC package and other

2. Standard seaworthy packageor customer-made

3. Port any port of China

Introduction

What is a seamless steel pipe?

A seamless steel pipe is a circular pipe having a hollow section and no seams around it. The seamless steel pipe is made of carbon steel, alloy steel, stainless steel ingot or solid tube blank, and then is made by hot rolling, cold rolling or cold drawing. Seamless pipes are considered superior to welded pipes as they are built using monolithic steel billets, with intrinsic mechanical strength, without seam welds.

Seamless steel pipe, as the name suggests, is a pipe without a seam or a weld-joint. Seamless steel pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids.

The production of our seamless pipes is tightly regulated and all of the pipes we stock have been fully tested to international standards to ensure we only supply the highest quality products.

Product Details:

Size

Maximum diameter: 48" (1219.2mm) minimum diameter: 1/8" (10.3mm)

Maximum thickness: 60mm mininmum thickness: 1.65mm

Standard

| ASTM A53 Gr.B | Black and hot-dipped zinc-coated steel pipes welded and seamless |

| ASTM A106 Gr.B | Seamless carbon steel for high temperature service |

| ASTM SA179 | Seamless cold-drawn low-carbon steel heat exchanger and condenser tubes |

| ASTM SA192 | Seamless carbon steel boiler tubes for high pressure |

| ASTM SA210 | Seamless Medium-carbon boiler and superheater tubes |

| ASTM A213 | Seamless alloy-steel boiler, superheater, and heat-exchanger tubes |

| ASTM A333 GR.6 | Seamless and welded carbon and alloy steel pipe intended for use at low temperatures |

| ASTM A335 P9,P11,T22,T91 | Seamless ferritic alloy-steel pipe for high-temperature service |

| ASTM A336 | Alloy steel forgings for pressure and high-temperature parts |

| ASTM SA519 4140/4130 | Seamless carbon for mechanical tubing |

| API Spec 5CT J55/K55/N80/L80/P110/K55 | Seamless steel pipe for casing |

| API Spec 5L PSL1/PSL2 Gr.b, X42/46/52/56/65/70 | Seamless steel pipe for line pipe |

| DIN 17175 | Seamless steel tube for elevated temperture |

| DN2391 | Cold drawn seamless prevision pipe |

| DIN 1629 | Seamless circular unalloyed steel tubes subject to special requirements |

Chemical Composition and Mechanical Properties

| Standard | Grade | Chemical Composition and Mechanical Properties | Mechanical Properties | |||||

| C | Si | Mn | P | S | Tensile STrength(Mpa) |

Yield STrength(Mpa) |

||

| ASTM A53 |

A |

≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.06 | ≥330 | |

| B | ≤0.30 |

- |

≤1.2 | ≤0.05 | ≤0.06 | ≥415 | ||

| ASTM A106 | A | ≤0.30 |

≥0.10 |

0.29-1.06 | ≤0.035 | ≤0.035 | ≥415 | |

| B |

≤0.35 |

≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥485 | ||

| ASTM A179 | A179 | 0.06-0.18 | - | 0.27-0.63 | ≤0.035 | ≤0.035 |

≥325 |

|

| ASTM A192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 |

≥325 |

|

| API 5L PSL1 | A | 0.22 |

- |

0.9 | ≤0.035 | ≤0.035 | ≥331 | |

|

B |

0.28 | - | 1.2 | 0.03 | 0.03 | ≥414 | ||

| X42 | 0.28 | - | 1.3 | 0.03 | 0.03 | ≥414 | ||

| X46 | 0.28 | - | 1.4 | 0.03 | 0.03 | ≥434 | ||

| X52 | 0.28 | - | 1.4 | 0.03 | 0.03 | ≥455 | ||

| X56 | 0.28 | - | 1.4 | 0.03 | 0.03 | ≥490 | ||

| X60 | 0.28 | - | 1.4 | 0.03 | 0.03 | ≥517 | ||

| X65 | 0.28 | - | 1.4 | 0.03 | 0.03 | ≥531 | ||

| X70 | 0.28 | - | 1.4 | 0.03 | 0.03 | ≥565 | ||

| API 5L PSL2 | B | 0.24 | - | 1.2 | 0.025 | 0.015 | ≥414 | |

| X42 | 0.24 | - | 1.3 | 0.025 | 0.015 | ≥414 | ||

| X46 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥434 | ||

| X52 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥455 | ||

| X56 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥490 | ||

| X60 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥517 | ||

| X65 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥531 | ||

| X70 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥565 | ||

| X80 | 0.24 | - | 1.4 | 0.025 | 0.015 | ≥621 | ||

Tolerances

| Pipe types | Pipe sizes(mm) | Tolerances |

| Hot rolled | OD<50 | ±0.50mm |

| OD>50 | ±1% | |

| WT<4 | ±12.5% | |

| WT 4~20 | +15%, -12.5% | |

| WT>20 | 13±12.5% | |

| Cold drawn | OD 6~10 | ±0.20mm |

| OD 10~30 | ±0.40mm | |

| OD 30~50 | ±0.45 | |

| OD>50 | ±1% | |

| WT≤1 | ±0.15mm | |

| WT 1~3 | +15%, -10% | |

| WT >3 | +12.5%, -10% |

Application

| Types | Application | |||

| Structure Purposes | General structure and mechanical | |||

| Liquid Services | Petroleum, gas and other fluids conveying | |||

| Low and Medium Pressure Boiler Tube | Steam and boiler manufacturing | |||

| Hydraulic Pillar Service | Hydraulic support | |||

| Auto Semi-shaft Casing | Auto sem-shaft casing | |||

| Line Pipe | Oil and gas conveying | |||

| Tubing and Casing | Oil and gas conveying | |||

| Drill Pipes | Well drilling | |||

| Geological Drilling Pipe | Geological drilling | |||

| Furnace tubes, heat exchangers tubes | Furnace tubes, heat exchangers | |||

| Chilled water pipe | Steam/condensate pipe | Heat exchanger pipe | Marine/offshore pipe | |

| Oil and gas pipe | Fire fighting pipe | Construction/structure pipe | Irrigation pipe | |

PACKING METHOD

1- Plastic caps plugged at the two sides of pipe ends

2- Should be avoided by the steel strapping and transport damage

3- Bundled signs should be uniform and consistent

4- The same bundle(batch) of steel pipe should be came from the same furnace.

5- The steel pipe has the same furnace number, the same steel grade, the same specifications.

Contact US

elena@lcteda.com

Related Products

Get in touch with us

*Mandatory fields